Sign up for the ControlAir newsletter.

Get news, updates, and offers direct to your inbox.

Here at ControlAir, we calibrate every single I/P Transducer we produce prior to shipping them to our customers. Often, we are asked, “if they have already been calibrated, why should I do it again?”. This blog post will discuss what is going on with our I/P Transducers and why it is important to calibrate them in-place at the installation.

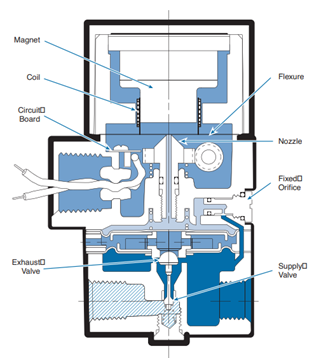

Let’s start this discussion by taking a look at how both the Type 500 and Type 550 I/P Transducers function. These two units are important to calibrate because they are open-loop analog devices. This means that they do not have internal feedback to make self-corrections. In both units, a copper coil is fixed to a flat spring (labeled coil and flexure). This coil sits in a stationary magnetic field and the flat spring is suspended just above the opening to a nozzle. When electrical current is run through the coil, the current induces its own magnetic field around the coil which acts opposite to the stationary magnet. These opposing forces move the flat spring closer or further from the nozzle which changes the pressure in a control chamber within the unit. This change in pressure alters the force acting on the supply valve and determines the pressure output of the unit.

Let’s start this discussion by taking a look at how both the Type 500 and Type 550 I/P Transducers function. These two units are important to calibrate because they are open-loop analog devices. This means that they do not have internal feedback to make self-corrections. In both units, a copper coil is fixed to a flat spring (labeled coil and flexure). This coil sits in a stationary magnetic field and the flat spring is suspended just above the opening to a nozzle. When electrical current is run through the coil, the current induces its own magnetic field around the coil which acts opposite to the stationary magnet. These opposing forces move the flat spring closer or further from the nozzle which changes the pressure in a control chamber within the unit. This change in pressure alters the force acting on the supply valve and determines the pressure output of the unit.

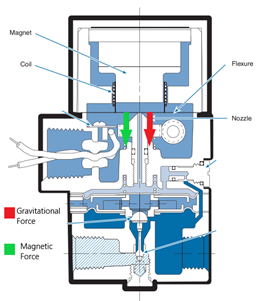

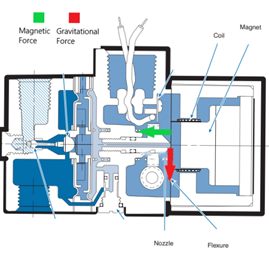

At ControlAir, these units are calibrated in the vertical position. Which means that there are two forces acting in the same direction on the flat spring. Those forces are the magnetic force and gravitational forces. When the unit is installed horizontally, those two forces still exist but now they are acting in different directions. The change in forces will change the position of the flat spring relative to the nozzle at a given current, which will change the pressure output of the unit. Therefore, it is important to recalibrate the unit in the position that it will be installed in to ensure expected performance. The same principle applies to the flapper and nozzle design of the Type 590 and Type 595 I/P Transducers.

The other reason that the calibration of I/P Transducers should be checked upon installation is that at ControlAir, these units are calibrated with set parameters such as supply pressure, ambient temperature, and flow rate through the unit. Changes in these parameters could impact the calibration of the unit. Therefore, its best to be sure to calibrate each unit to your specific application and operating conditions. Instructions on how to complete the calibration process can be found in the instruction manual in the box with the unit, on the unit’s product page on our website or a video demonstration can be followed for further explanation.

While it is important to calibrate the previously discussed units in place at the parameter of us, this practice is not necessary for the Type 900 or Type 950. These units are closed loop units that have internal feedback. These units utilize an onboard pressure sensor to check down stream pressure and make self-corrections. They are truly a plug-and-play option.