Sign up for the ControlAir newsletter.

Get news, updates, and offers direct to your inbox.

Whether you are replacing an existing regulator or starting a new project, having answers to the following questions will help us provide you with the appropriate regulator.

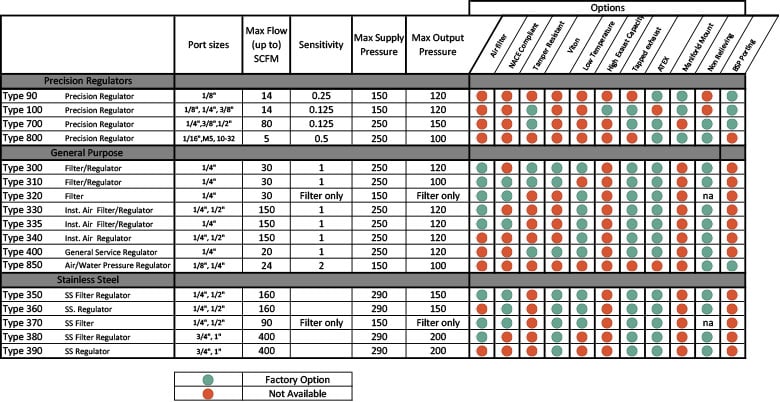

All regulators have a maximum supply pressure. The spring range selected for output pressures should be based on the desired regulated pressure range. The output pressure setting should be in the middle of that spring range for best results.

Related blog: Choosing the Correct Regulator:Part I – Pressure

Different types of media (other than air) may require special materials for wetted components. ControlAir has many options at its disposal, so be as specific as possible when giving us this information.

Related blog: Choosing the Correct Regulator:Part II – Media

Picking a port size for a new project should not be the determining factor, but if you are replacing an existing valve, it is important to know the correct thread size.

Related blog: Choosing the Correct Regulator:Part III – Porting

It must be determined how much air flow capacity is required by the application. As flow reaches maximum capacity of a regulator, performance characteristics can change. Droop, accuracy and sensitivity can be affected by flow.

Related blog: Choosing the Correct Regulator:Part IV – Pressure

In some applications such as force counterbalance, quick and rapid movements of air cylinders might require a large amount of air to be displaced from the cylinder and back through the regulator as exhaust.

Related blog: Choosing the Correct Regulator:Part V – Exhaust Capacity

Is the regulator being used in a hazardous environment? Is it going to be exposed to corrosive materials ie. Salt water/air, wash down bleach and water?

Related blog: Choosing the Correct Regulator:Part VI – Environmental Considerations

For applications that are sensitive to pressure variations and require accurate and repeatable pressure adjustments, a precision regulator may be required. For applications that are less sensitive to large pressure variations, a general-purpose regulator may be adequate.

Related blog: Choosing the Correct Regulator:Part VII – Sensitivity