Sign up for the ControlAir newsletter.

Get news, updates, and offers direct to your inbox.

There are many, many choices when it comes to air pressure regulators. There are FRL’s, Filter Regulators, and units that are regulators only. Add to that, different material types for both the body and diaphragm, and a range of accessories, all add some complexity to the decision process. Not all applications are alike, which makes sense that there are multiple regulator types for a given port size, pressure range and capacity range. Obviously, there are many combinations that will work for an application, but what are some of the signs that you need to move from a generic or general-purpose product to a precision regulator?

Before we answer that question, it would be best to understand the basic performance differences between a precision and general-purpose regulator. The focus should be on the performance characteristics, rather than shape or size. When discussing accuracy, we need to consider resolution, repeatability and sensitivity. These terms can sometimes cause confusion and be used incorrectly. To make matters even more cloudy, some of these characteristics are dependent on each other.

Accuracy- this can be a generic term used for many facets of regulator performance. Most people tend to use this term when “looking for a better regulator”. The determination of a “better or more precise regulator” will depend on the application and what is the obvious shortfall in the current regulator. For this discussion’s sake, we will focus on resolution, droop, sensitivity and repeatability.

This discussion should probably start with sensitivity. Sensitivity is a measurement of how much the downstream pressure has to change before the regulator mechanics will compensate and change to the previous set point. Most manufacturers give this specification in inches of water column. The smaller the number the more sensitive the regulator. Most precision regulators are 0.25” or less of water column while most general-purpose regulators are around 1”. Some things that affect the sensitivity of a regulator are diaphragm design and materials, valve and valve seat materials, flow rates for a particular valve and even downstream volume requirements. This sensitivity usually comes at a price. There is normally some sort of designed air consumption required to get this increase of sensitivity.

Regulator mechanics will fluctuate in order to regulate the downstream pressure. Internal springs are compressed or relaxed, supply valves are opened and closed and relief valve operation can add variability to the system as well. When the regulator is changed from a static to a dynamic state for a moment, how close to the original pressure does it return? This trait is called repeatability, but it goes hand in hand with sensitivity and both will affect resolution, which will be discussed later.

There is a phenomenon in regulators called droop. A simple definition of droop: as flow through a valve increases, all other things being equal, the output pressure will fall. Things that affect droop are valve design and flow and probably most importantly, spring range. The larger the spring range, the more prominent the effect of droop on a regulator. Some regulators have design features to minimize this effect, which usually requires the use of something other than a spring to set the force balance requirement in a regulator. If you look at a standard flow curve, you can see that as flow increases, the output pressure will decrease. If you increase flow past what the valve was designed to handle, this pressure will fall off rapidly.

Resolution is a fairly simple concept; how fine can you adjust the regulator and have output pressure react to your input changes. Can it be adjusted to +/- 1 psi or +/- 0.1 psi? Let’s say you are trying to adjust to 5.5 psi, the first thing to think about is spring range. We recommend that you stay with in the middle 2/3 of a spring range to get the best performance. In this case, a 0 to 20 psi range would be appropriate. A more common range would be 0 to 15. Some precision regulators have an assortment of special ranges, more than the normal process/general purpose regulators (0 to 30, 0 to 60 and 0 to 120). Resolution not only has to do with the spring range in a regulator but also its sensitivity. The more sensitive the regulator, the less chance of having to adjust and readjust to find the “perfect set point”. This could otherwise be called “hunting” which is a common phenomenon in an improperly set servo loop. In this case, you are the part of the servo loop, physically trying to fine-tune a set point pressure. Now to make this a bit more complicated, you have to bring back the previously discussed repeatability. If your regulator is only repeatable to +/- 0.25 psi, it will be a futile and frustrating effort to try and maintain a +/-0.1 psi accuracy.

There are a few things you may be experiencing in your air regulator application that may require you to upgrade to a precision regulator.

You cannot seem to get the right set point because you keep adjusting the regulator and it jumps to either side of your required set point. In other words, your regulator does not have the resolution you need. This could be due to improper spring range but it would seem to indicate a problem with repeatability and/or sensitivity. Your regulator is not reacting quickly enough to your commands and it then resets to a different pressure than needed. Another possible reason you could be having difficulty; the exhaust capacity is too small, which can add adjustment difficulties for larger volumes of regulated air. See our video on our Type-100 regulator vs. Type-330 exhaust capacity.

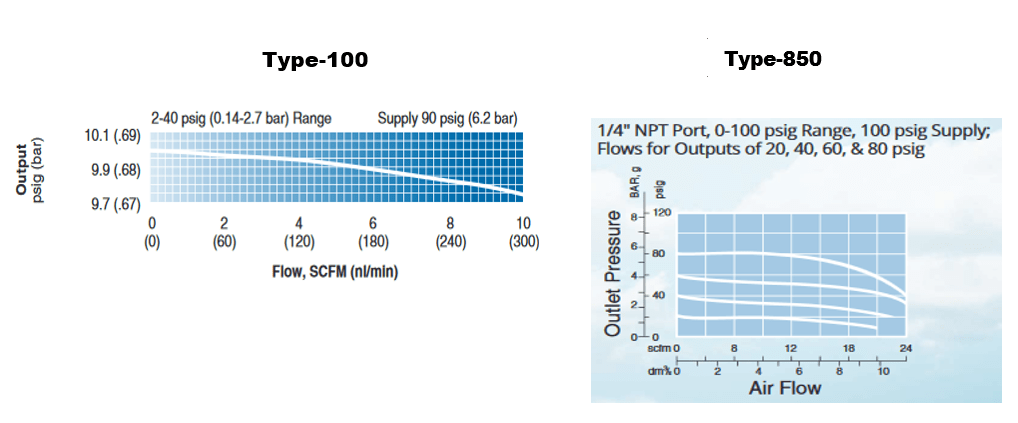

Your downstream pressure changes too much with flow and temperature even though you have not adjusted the regulator setting. Increase the flow or change the temperature, the greater the risk that the downstream pressure changes as well. General purpose regulators do not factor in temperature or flow very well. Common droop curves (flow curves) can illustrate this very well. Below you will see an example of ControlAir’s Type-100 precision regulator vs. a Type-850 general purpose regulator.

At first glance, the slope looks similar, but the pressure drop with increase flow for the Type-100 is less than 3% between 0 and 10 scfm. Compare that to 15 to 20% for a Type-850 general purpose regulator.

I have many downstream components that are affected by supply pressure fluctuations. Your current regulator may not be sized properly for the required flow. If you look at droop curves for a particular regulator there can be a steep drop off in output pressure as flow increases. A precision regulator will compensate for increased flow better than general purpose regulators. Forward flow capacity can be an issue, but it is important to consider exhaust flow requirements. Some regulators have 500 times the forward flow capacity as compared to their relief capacities.

When picking a regulator, it is important to understand not only your specific application parameters, but the simple characteristics of the regulator being used. We have a list of 7 questions to answer to properly pick a regulator. Please contact our tech support for help with your next regulator requirement.