Sign up for the ControlAir newsletter.

Get news, updates, and offers direct to your inbox.

1) What is a “first cut” regulator?

1) What is a “first cut” regulator?

A “first cut” regulator is a device that accepts a high-pressure source of gas or compressed air and is capable of “cutting” it or reducing it to a lower usable pressure, typically referred to as instrument air pressure. Instrument air pressure is typically any pressure < 150 psig.

2) What are their limitations?

“First cut” regulators are limited by design and are used primarily as a “rough cut” reduction in pressure from 1000-6000 psig down to 225 psig and below. Due to the nature of their design, they are not very sensitive to changes in pressure, therefore, output pressures can fluctuate on the same magnitude as the supply. ie A 10% change in supply pressure can equate to up to a 10% impact on output pressure. Therefore, it is best to use a balanced pintle design regulator for your desired final output pressure. A balanced pintle design will smooth out fluctuations in supply pressure changes and not pass them downstream to your instrumentation.

3) How to choose a regulator?

To choose a regulator, you need to know the highest pressure the regulator will be seeing and what level of output will be needed for the application. For safety reasons, the regulator must be rated to accept the supply pressure that will be introduced. Second, it is best to choose a spring range that is 2X that of your desired output pressure. This range allows the regulator to perform at it’s optimum as the spring is not fully compressed allowing quick response to changes in supply pressure.

The next consideration is flow. How much volume of the media is required for your application? You need to calculate the volume required for your point of use. The flow diagrams and Cv flow coefficient values are typically available on regulator technical specification sheets.

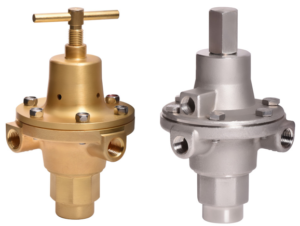

Another important consideration is what materials are to be exposed to the wetted surfaces of air or gas routing. It is important to note if the material will be compatible with the environmental considerations. One example is that brass, which is a common material for regulator designs, is not compatible with the presence of hydrogen sulfide (H2S) which is a common element in natural gas (sour gas) processing. The use of 316 stainless steel is more compatible for these installations.

4) Some common Commercial Applications

a. Compressed air or gases

2. Upstream Processing

a. Natural gas processing

3. Farm Taps

a. Rural natural gas extensions for farm usage

ControlAir has over 30 years of design and manufacturing experience of air and gas regulators, feel free to contact us to discuss your application in more detail as to offer the best overall solution.